Introduction[]

The field frames of a cheiroballistra consist of bars, rings and pi-brackets. This article describes two ways to attach the bars and the rings together. The first method is by riveting and the second by welding. If it happens that you screw up while riveting, you can fortunately save the day with some extra work and welding equipment.

Attaching the pi-brackets to the bars is described in this article.

The process step-by-step[]

Marking the rivet holes[]

The Greeks and Romans almost certainly punched rectangular holes into the field-frame rings instead of going through the trouble of carefully measuring and drilling the holes. After all, the distance of the field-frame bars was not critical, nor was their exact alignment. However, here we're reconstructing the cheiroballistra, which does have exact dimensions, so "about right" is not good enough.

Start by taking a pair of compasses and measuring about ~3,5cm (3,5d/2):

Draw a circle with that radius (3,5d/2) to a stout piece of cardboard:

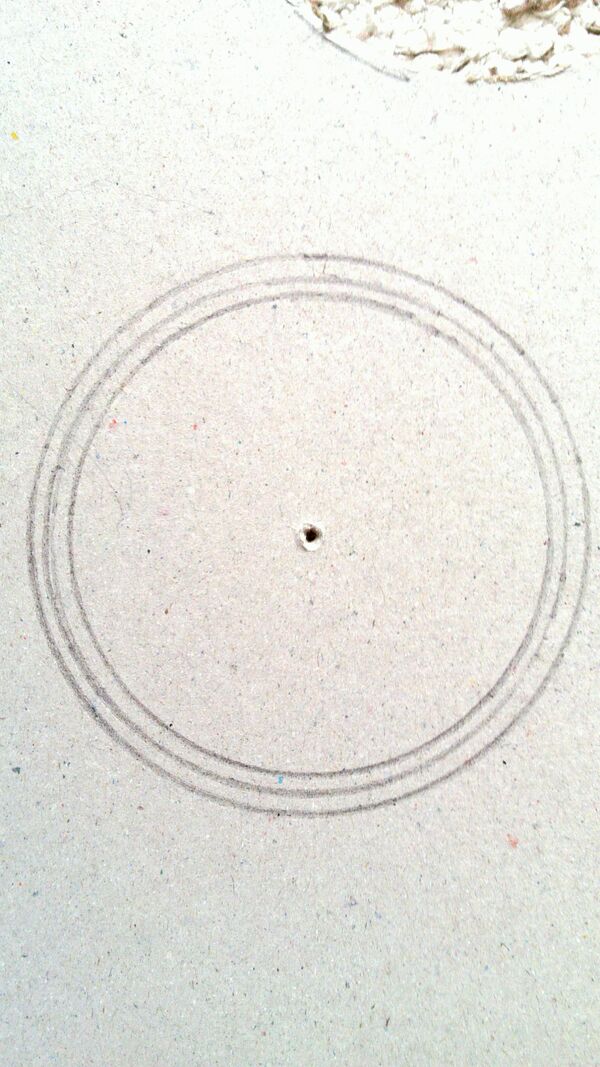

Draw two additional circles to some distance from the first:

Cut the circle from the cardboard and cut two small notches to it's sides. These notches will help place the holes for field-frame bars properly. As can be seen, the notches are 3,5d apart, which equals the distance of the bars as given by P.H.:

Next cut away the center part to make aligning the template to the exact centre of the field-frame bars becomes easier. Then, using the cardboard template as a guide, mark the places of the holes for field-frame bar tenons:

Drilling holes to the rings[]

It's best to drill holes to the rings for the rivet-ends of the field-frame bars. This helps ensure the bars are aligned perfectly while welding or riveting. For riveting, the hole does not have to be big - just enough help the tapered punch to go through cleanly and easily. For welding, the hole should be large enough to allow passing through the riveted ends of the tenon ends of the bars.

If, while marking the locations for the tenon holes in the rings you notice that the field-frame rings are too narrow, you can widen them by welding extra piece of steel to them as shown below:

Riveting[]

This is the more authentic method of assembling the field-frames. Although welding was possible in the Roman times, riveting is easier, i.e. requires less skill. If you manage to screw up the riveting part, you can save the day by welding the bars and rings together (see below).

First make a rectangular punch with a tapered tip from any scrap steel you might have. The diameter of the punch should be somewhat larger than that of the tenon end of a field-frame bar; this allows small adjustment to the angle of the bars before riveting. The tapered end of the punch should be slightly smaller than the holes you drilled to the rings, so that the punch centers itself when you punch through the rings:

Do not use the field-frame bar itself to punch through the bars.

Heat each ring in a forge until it's yellow hot and punch through the circular holes in the rings using the improvised punch:

NOTE: Unlike in the picture above, make the sure that the rectangular hole are roughly in the correct angle. If you need to adjust the angle, you can probably do it like described here.

Once all the holes have been punched, you can decide whether to rivet the tenon ends of the bars hot or cold. In retrospect, I'd suggest riveting them cold. If the holes for the tenons are slightly larger than the tenons of the bars themselves, you can adjust the angle of bars to some degree. If that's not enough, correct the angle position as described here. Once the angle is correct, attach each field-frame bar to a vise, push it's tenon through the hole in the ring and rivet them together:

Hammer the rivet slowly, adjusting the bar angle as necessary. If you mess the angles up now, you need to correct the bar angle later, which is rather tedious.

The resulting field-frames should look similar to those below; note that the angle of the bars is incorrect, especially for the left curved bar:

You should not end up with such a wrong angles if you follow the instruction given in this article closely.

Welding[]

The field-frames can also be assembled using electric welding equipment. This is especially useful if manage to screw up the alignment of the field-frame bars badly while riveting, and there's no way to correct it. This happened to me, as can be seen from the pictures above.

When welding the field-frames together, it's beneficial to drill holes in the rings first, and pushing the tenon end of the bar through it:

Once the bar is perfectly aligned with the ring, weld them together from all sides:

Once all bars have been welded to the rings, you should have field-frames that look like this (or better yet, prettier):

Tips[]

Correcting hole angle in the rings[]

If the holes in the rings are not in the correct angle, you should be able to fix that using the following process:

- Take a piece of rectangular steel that's exactly the same diameter as the punched hole and bend it to a L-shape

- Heat the ring very hot (yellow)

- Push the L-shaped tool through the hole

- Twist the L-shaped tool to adjust the angle

- Correct any unwanted bends in the ring using a hammer

Note that I have not actually tested this, but I don't see why it would not work.

Correcting the bar angle[]

If you did a good job, you should not need to correct the bar angle after the field-frame is assembled. However, should the need arise (and you used riveting), all is not lost. Simply heat each field-frame ring in forge:

When the ring and bars are hot enough, twist the bars along their longitunal axis to the correct position:

Avoid punching the rings with the field-frame bars[]

While it might seem like a good idea to punch through rings using the field-frame bar itself, there are two good reasons not to do it:

- The curved field-frame bars tend to bend when used as punches

- It's very easy to punch too deep by mistake, so that the actual field-frame bar sinks into the ring. This makes adjusting the angle of the bar impossible afterwards, as well as makes the field-frame lower than it should be.

This picture shows what your field-frame will probably end up looking like if you decide to try this "time-saving" technique out regardless of these warnings: